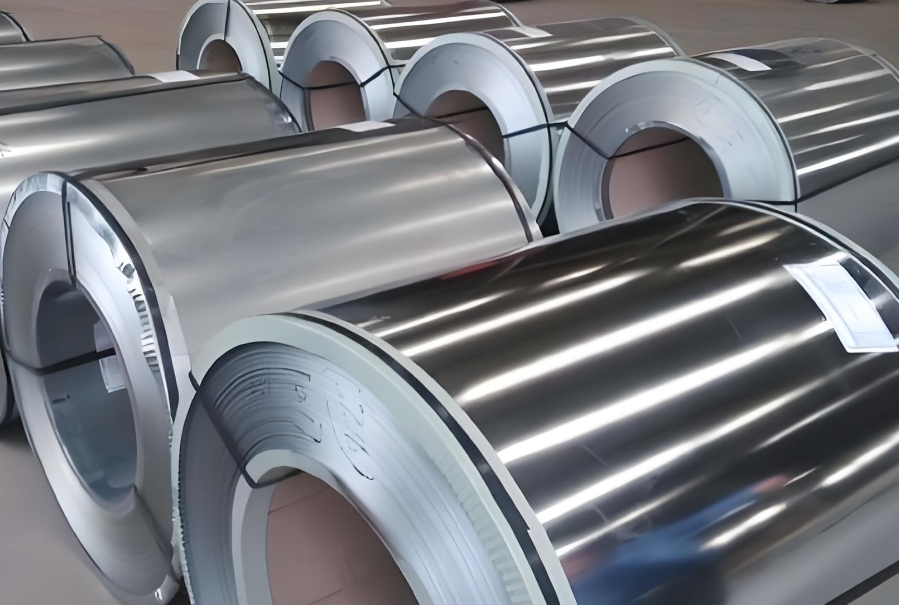

Electrical Steel for Power Equipment

Electrical steel is integral in the manufacturing of power equipment, serving as a core material. With its specialized magnetic properties, it optimizes energy transfer, enhancing the efficiency and reliability of power equipment. This crucial component is instrumental in powering various electrical applications across different sectors.

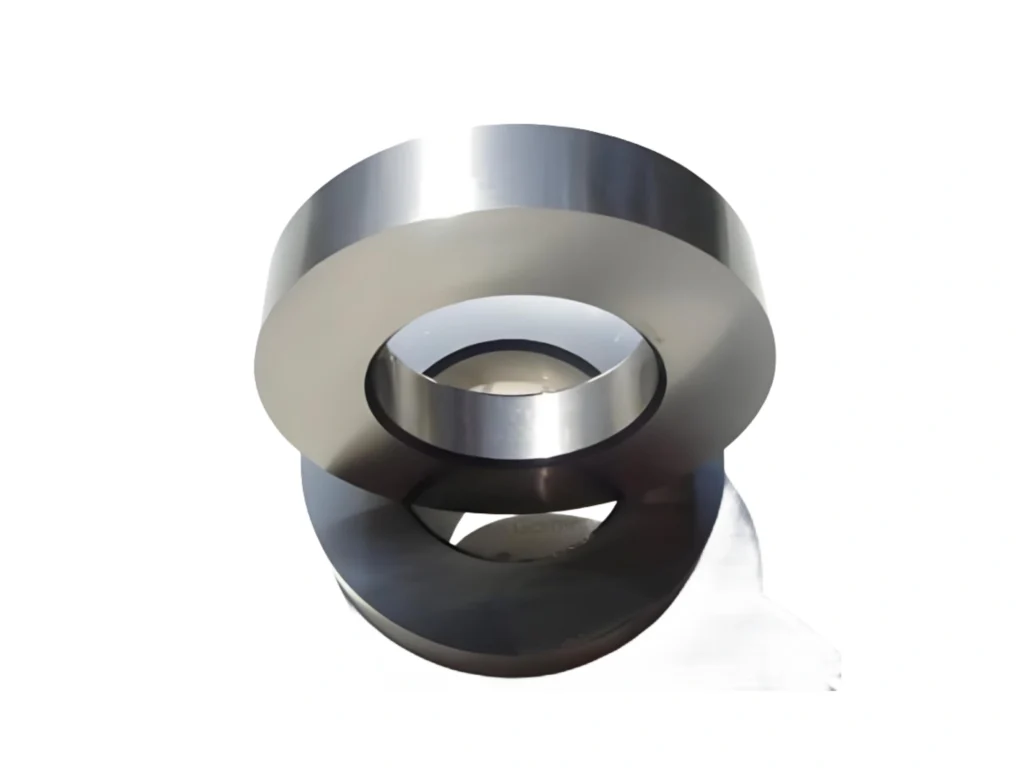

High magnetic permeability: Electrical steel exhibits high magnetic permeability, facilitating efficient conduction of magnetic flux within the core of power equipment such as reactors, inductors, and magnetic shields. This property enhances energy conversion and improves the performance of various power distribution and control systems.

Low core losses: Engineered for minimal core losses, electrical steel reduces energy dissipation within the core of power equipment like reactors, inductors, and magnetic circuits. This characteristic ensures optimal energy efficiency during operation, minimizing wastage and enhancing overall system reliability.

- Low eddy current losses: Electrical steel is designed to minimize eddy current losses, which occur due to induced currents circulating within the material. This feature is crucial for power equipment like magnetic shields, reactors, and inductors, reducing energy wastage and maintaining system efficiency.

High saturation magnetic flux density: Electrical steel possesses high saturation magnetic flux density, enabling it to maintain stable magnetic properties even under high magnetic fields. This characteristic is advantageous for power equipment like reactors, inductors, and magnetic circuits, ensuring reliable operation under varying conditions and loads.