High Quality

All operations in Eugenia Tech are audited by and comply with VDA6.3

Fast Delivery

All delivery are controlled by ERP systems automatically,reducing waiting time.

Best Warranty

Aftersale engineer team will appear on site within 5 days if VISA available after receiving customer complains.

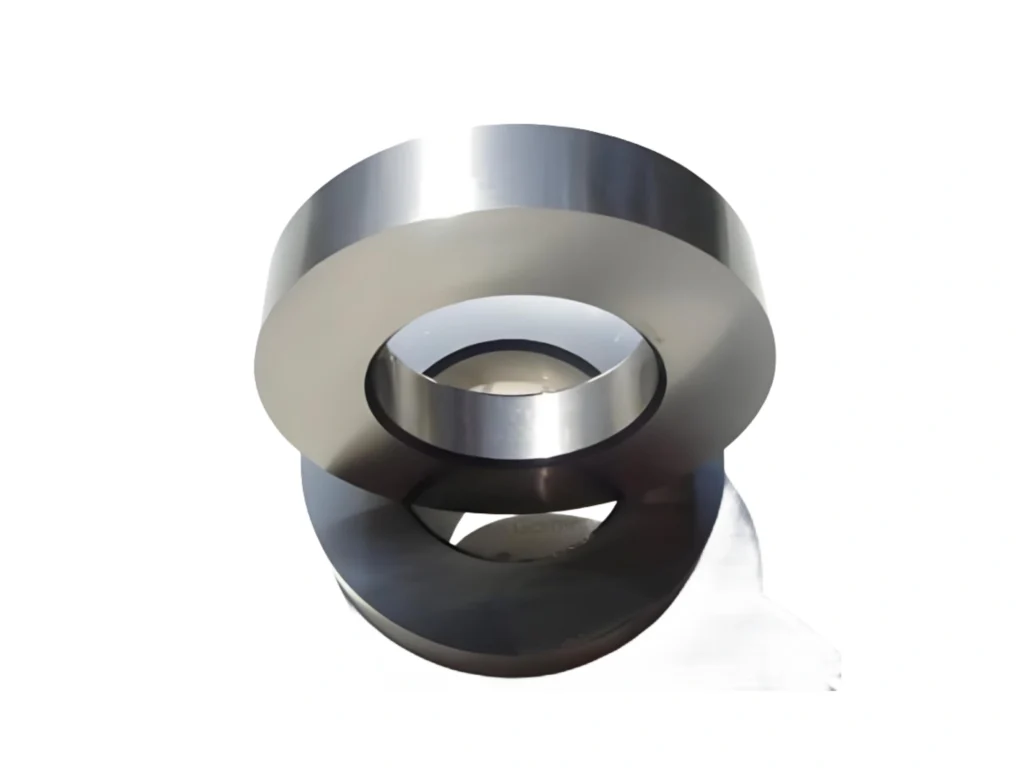

motor-grade electrical steel

Electrical Steel

customized electrical steels

Silicon Steels

Transformer steels

About Us

Nowdays electricity has been the most important form of power,however over 50% of the planet lacks complete electric facilities.While some industrial countries like East Asia,North America and West Europe are working on a green energy revolution,others are troubled by aging basic electric facilities,backward technology and lacking engineer team.

Eugenia Tech is committed to enable customer the abilities to produce distribution transformers and other related electric products with anvanced processsing skills.Product design,raw material source ,machine source and on site technical support are its main buiness.

Eugenia Tech makes the future brighter!

Help customers achieve rapid and health developments through our efforts.

Electrical Steel Production Process

Alloying

The process begins with the selection of raw materials, typically iron ore and silicon. These materials are combined in precise proportions to create the desired alloy composition. Other alloying elements may also be added to enhance specific properties.

Casting

The alloy is melted in a furnace and then cast into large ingots or slabs using continuous casting or ingot casting techniques. This initial casting forms the raw material for further processing.

Hot Rolling

The cast ingots are heated and passed through a series of rolling mills to reduce their thickness and shape them into coils or sheets. This hot rolling process helps to refine the grain structure of the steel and improve its mechanical properties.

Cold Rolling

The annealed coils are then cold-rolled to further reduce their thickness and improve their surface finish. Cold rolling also imparts additional strength and dimensional accuracy to the steel.