Introduction

Overview of the importance of electrical steel in motor design

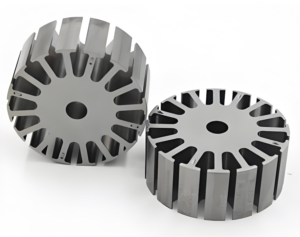

Electrical steel, also known as silicon steel, plays a critical role in motor design due to its unique magnetic properties. The magnetic core of a motor, typically made from electrical steel, is essential for converting electrical energy into mechanical energy. The magnetic properties of electrical steel, such as high magnetic permeability and low core losses, are crucial for achieving efficient energy conversion and optimal motor performance. Therefore, understanding the importance of electrical steel in motor design is fundamental for engineers and designers in various industries.

Electrical Steel Applications in Motors

Core materials selection process

When selecting core materials for motors, engineers must carefully consider factors such as magnetic properties, core losses, and manufacturing feasibility. Electrical steel, with its high magnetic permeability and low core losses, is often the preferred choice for motor cores due to its excellent performance and reliability. The selection process involves evaluating different grades and thicknesses of electrical steel to ensure optimal motor performance and efficiency.

Enhancing motor efficiency with electrical steel

The use of electrical steel in motor construction significantly enhances motor efficiency. Its high magnetic permeability allows for the creation of strong magnetic fields, while its low core losses minimize energy dissipation within the core material. This results in improved power output and reduced energy consumption, leading to higher overall motor efficiency.

Improving motor performance through electrical steel utilization

Electrical steel plays a crucial role in improving motor performance in various ways. By providing a highly efficient path for magnetic flux, electrical steel ensures that the motor can operate smoothly and reliably. Additionally, its magnetic properties help to maintain stable motor operation and reduce electromagnetic noise during operation. Overall, the utilization of electrical steel enables engineers to design motors that are highly efficient, reliable, and capable of meeting the performance requirements of diverse applications.

Case Studies

Examples showcasing the use of electrical steel in motor design

Numerous case studies demonstrate the widespread use of electrical steel in motor across various industries. For instance, in the automotive sector, electric vehicles (EVs) utilize high-efficiency motors with cores made from electrical steel to maximize performance and range. Similarly, industrial applications such as pumps and fans benefit from the use of electrical steel cores to achieve optimal efficiency and reliability.

Conclusion

The key role of electrical steel in motor design

In conclusion, electrical steel plays a pivotal role in motor design due to its unique magnetic properties. As the primary material used in motor cores, electrical steel enables efficient energy conversion and optimal motor performance. Its high magnetic permeability and low core losses ensure that motors operate with minimal energy loss, leading to improved efficiency and reliability.

Benefits and importance of utilizing electrical steel in motors

The utilization of electrical steel in motors offers numerous benefits and is of paramount importance in modern engineering. By selecting electrical steel as the core material, engineers can enhance motor efficiency, increase power output, and reduce energy consumption. Additionally, electrical steel contributes to stable motor operation and reduced electromagnetic noise, further enhancing overall performance. In summary, the use of electrical steel is essential for achieving optimal motor and ensuring the reliable operation of motors in various applications.